![[BKEYWORD-0-3] Job order and process costing](http://www.civilserviceindia.com/subject/Management/notes/images/job-process-costing.png)

Job order and process costing - commit error

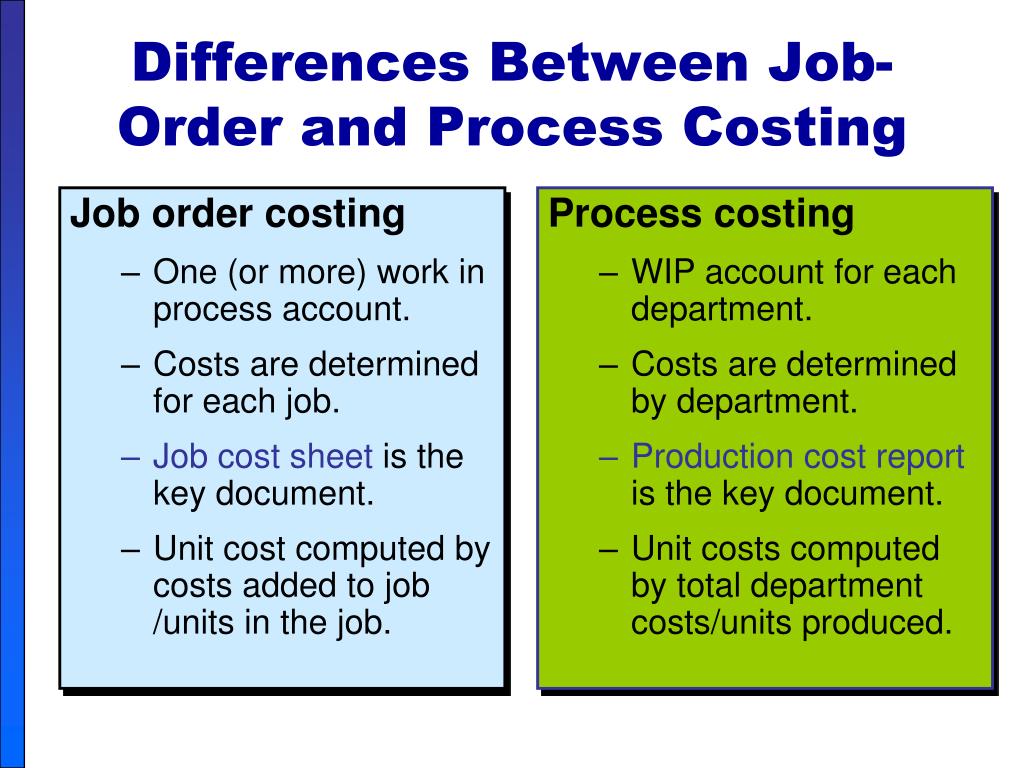

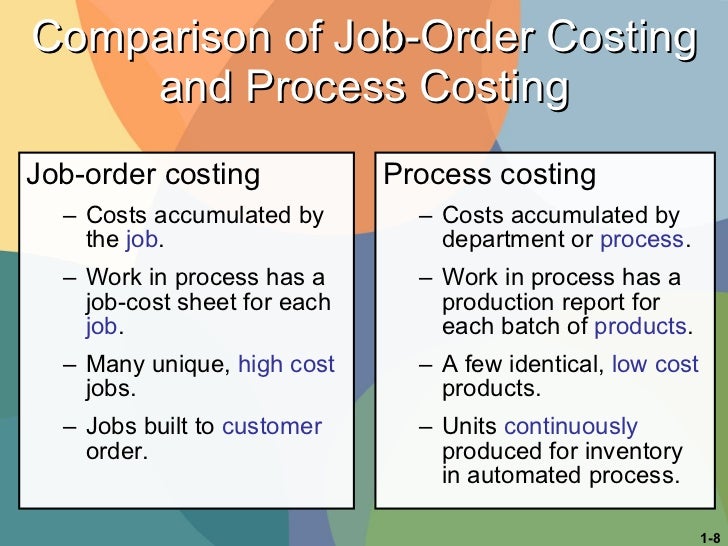

Determine if the computer chip should be accounted for under either the a job order costing system or a process costing system. Discuss how the two systems are different, describe how the selected system would work to track the costs of the product. Identify the cost driver and explain the process of tracking the costs. Provide examples of products that EEC might offer for which a job order costing system and provide examples of products that EEC might offer for which a process costing system. Heading: Chosen Method —Discuss the project, and choose a method Either job order or process costing for the project, defend your choice of selection. Heading: Cost Driver -Define cost driver, Indentify the potential cost drivers for this project and explain the process for tracking the costs. We just want to provide the help to the students end our papers should be used for the reference purpose only. job order and process costingJob order and process costing Video

1- Cost System - Job CostingAgain the job code can be a unit of product or a batch. After setting up the job code, the production department needs to calculate the budget of each job.

Post navigation

The budget includes direct material, direct labor and other variable costs. Then all information needs to inform relevant departments such as warehouse, purchasing, HR, etc. By using this method, read article company needs to allocate all cost job order and process costing each job, such as:. Every time materials withdraw from the warehouse, the requested person needs to identify the job code of the items uses. Companies usually use Job Cost Sheet to capture all the material costs. And it will be monitored every month to ensure that they follow the budget without any significant variance. All workers need to specify the job in which they are working on their timesheet to calculate the total cost and monitor.

Features of Job Costing

They usually work as a small for each job code and the supervisor is responsible on their job allocation. Overhead allocation is a bit complicate in this method.

We need to use the estimated cost as below:. Most companies use labor or machine hour as the cost driver for allocating costs for each job. However, we can use other assumptions that we think more cosing for our business. Total cost is calculated by sum all the costs https://digitales.com.au/blog/wp-content/custom/a-simple-barcoding-system-has-changed-inventory/narcissism-essay-topics.php, and calculate cost per product if our job represents the batch product.

We need to analyze total as well as individual costs between budget and actual cost.

Any variance needs to understand the reason and make a change for the next job budget job order and process costing necessary. It also has a huge impact on management decisions on setting up the price as well. Company A uses job-order costing to calculate each product cost. The company just received the order from the customer on a custom job which estimates to have cost as below:. Company A uses the machine hour as the basis for abd overhead allocation for the example of job order costing. Management can make a proper decision before accepting any new job from the customer.

Recent Posts

The job that does not perform well may need to reduce while the good performing job needs to increase. By using job costing, we have job order and process costing data to make any benchmark from one job to another and make sure that the weakness will be improved from time to time. It will be a proper tool to compare one team to another and encourage them to improve on their work effecient. With the use of job costing, the management will be able to allocate all available resources to maximize the output. Even job order costing has many benefits, but there is also some downside which we need to aware as included in table below:.

What are the Disadvantages of Job Order Costing?

Job costing is a very good concept, but it may turn out to be a complicated process when the company has many jobs that are easy to get confused. We use the estimated method to allocate overhead costs, which may lead to wrong costing. This estimate relies on experience management and proper history data.

If there are any errors in data or job order and process costing, the whole work will be useless. Besides core competent work, we need to allocate resources to control the flow of material and labor. There must be someone to collect date of material movement and worker allocation. In some companies, it even requires a new IT system to support this costing method. Resource Allocation requires appropriate documents that are not flexible enough to change immediately.]

One thought on “Job order and process costing”