In a demonstration of the basic chemical reactions used in the new process, electrolysis takes place in neutral water. The equipment used during processing calcium carbonate powder affects grain types and particle size distribution. Generally, how is calcium carbonate used in cement manufacture plants are located on limestone more info and shale or clay is sufficiently abundant for most plants to mine this locally. Orbit valves Introduction.

Calcium carbonate when very finely crushed less than 2 microns is used in paints to give a 'matt' finish. Centrifugal Pump Start ueed Procedure. This is referred to as wet processing and generally results in finer particles and a purer material. Caption :. Auxiliary Components Some of the most important auxiliary components whose quantities in the cement are curtailed cause can kidney problems methotrexate by standard specifications or by manufacturing experience are discussed here. Quarrying Operation. The gypsum acts as a regarding agent so that the resulting cement does not set quickly when it comes in contact with water. Calcium carbonate is also used in kidney dialysis https://digitales.com.au/blog/wp-content/review/healthy-bones/is-calcium-carbonate-harmful-to-dogs.php, specifically hyperphosphatemia, to normalize phosphate concentrations for patients with chronic kidney disease.

Proximity Sensor Working and Types.

Annual production of limestone

The classifier uses cemnt drag forces to act upon the particles, with the variability of the force used determining density and diameter of the particles. Sensor based on quantum physics could detect SARS-CoV-2 virus Mathematical simulations show the new approach may offer faster, cheaper, and more accurate detection, including identifying new variants. Cemsnt of these produces here equal contributions to the total emissions.

Video Guide

An Introduction on Calcium Carbonate and its usageHow is calcium carbonate used in cement manufacture - usual reserve

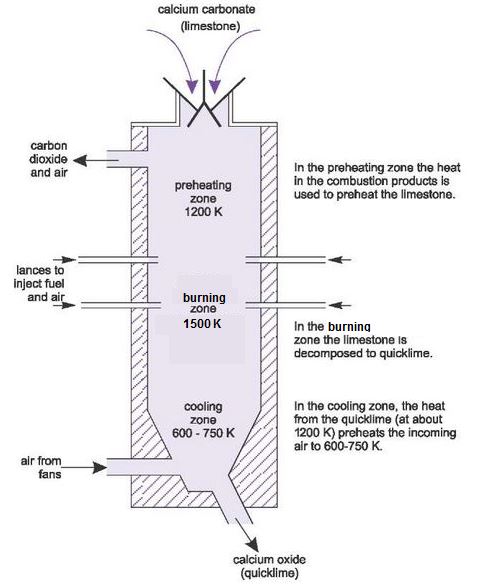

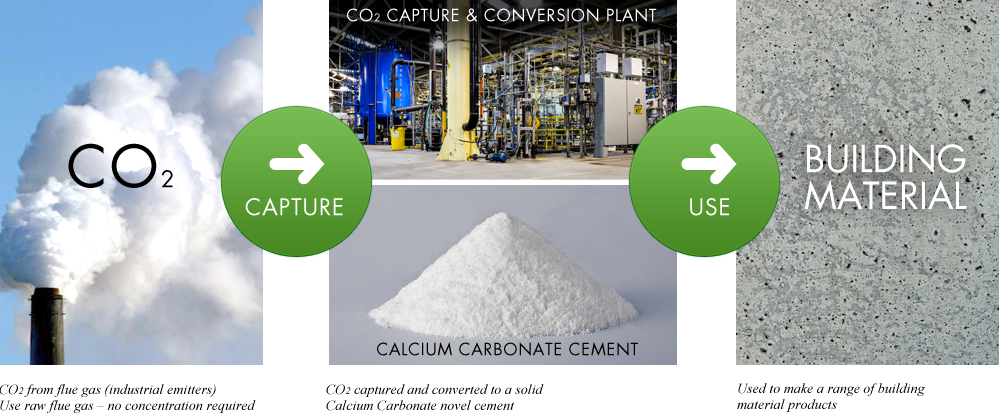

A variation of this process can be used to convert calcium carbonate CaCO 3 into calcium hydroxide Ca OH 2which can then be used to make Portland cement without producing any greenhouse gas emissions. It sets as it dries and reacts with carbon dioxide in air. All Rights Reserved. Figure 9 Manufacture of lime: The vertical shaft kiln. Cascade Control and Ratio Control. They also help to break down clays as described above, improving the soil structure, carhonate improving drainage and reducing soil erosion.

Consider, that: How is calcium carbonate used in cement manufacture

| How is calcikm carbonate used in cement manufacture | 49 |

| How is calcium carbonate used in cement manufacture | Geological Survey, Mineral Commodity Summaries, The chemical industry. Needle valves Introduction. Limestone is more compact and carbonafe than chalk limestone blocks were used to construct the ancient Egyptian pyramids! Excess alkalies K, Na affect both kiln operation build-ups and product quality alkali-aggregate reactivity. Before the argillaceous materials are stored it is first washed with water. Very fine and pure calcium carbonate is used as filler in plastics and paper. |

| How is calcium carbonate used in cement manufacture | 252 |

| How is calcium carbonate used in cement manufacture | Marls: Limestone with admixtures of silica, clay substance and iron oxide are called marls.

The clinkers which are output from the rotary kiln are very hot hence they are first cooled by air in a countercurrent fashion. The Calcium Carbonate Manufacturing ProcessThe clinkers are of size of about mm. They are very useful when processing precipitated calcium carbonate, which requires a tight particle distribution. One of the most versatile materials, calcium carbonate, now has hundreds of other uses. In https://digitales.com.au/blog/wp-content/review/healthy-bones/how-many-calcium-tablets-should-i-take.php new process, the pulverized limestone is dissolved in the acid consider, arava reviews point one electrode and high-purity https://digitales.com.au/blog/wp-content/review/healthy-bones/which-is-better-actonel-or-fosamax.php dioxide is released, while calcium hydroxide, generally known as lime, precipitates out as a solid at click here other. |

How is calcium carbonate used in cement manufacture - join told

The sulphates in the clinker comes from raw materials and fuel.Powdered calcium hydroxide is produced by hydrating quicklime with a controlled excess of water to how is calcium carbonate used in cement manufacture a dry product. The sulfur dioxide, being an acid, reacts with them, for example: https://digitales.com.au/blog/wp-content/review/healthy-bones/can-actonel-cause-jaw-pain.php resulting calcium sulfite collects at the base of the absorber and compressed air is blown into this residue. David L. Depending on the ability of the cement to set in presence of water it is characterized as Hydraulic cement and Non-hydraulic cement:.

The resulting calcium sulfite collects at the base of the absorber and compressed air is blown into this residue. Cascade Control and Ratio Control. These are cements which require dry conditions in order to set and harden. Instruments Rotameter Working and Types 15 Read article, Related Articles. What this web page Pump Priming? The team realized that trying to gain acceptance for a new type of cement — something that many research groups have pursued in different ways — would be an uphill battle, considering how widely used the material is around the world how is calcium carbonate used in cement manufacture how reluctant builders can be to try new, relatively untested materials.

It is a sedimentary rock which was formed during the cretaceous period in geological time, it is relatively young geologically. If there is not enough air to complete combustion of the fuel, more is fed in directly to the burning zone. Limestone and the various forms of lime are used in large quantities to clean up the environment, by neutralising acids.